In recent decades, shippers and warehouse managers around the world have been embracing automation solutions, including artificial intelligence-powered software, robotics technologies, and other innovative tools. Of the many robust new solutions that have emerged in the past decade, pallet and parcel dimensioners are some of the most practical.

Click Here: Automate Your Dimensioning Process & Integrate the Best Dimensioners With Your Warehouse

This article explains how dimensioners work, the different types, and how they improve your warehouse efficiency and customer satisfaction.

Types of Dimensioners: Parcel and Pallet

There are two types of dimensioners: parcel dimensioners and pallet dimensioners.

A. Parcel Dimensioner

A parcel dimensioner is the smaller of the two solutions. These devices typically fit on a counter or desktop and feature a small, raised platform. When a team member places a parcel on the dimensioner, the device will automatically gather height, depth, width, and weight measurements.

B. Pallet Dimensioner

Pallet dimensioners function in the same fashion as parcel dimensioners. However, pallet dimensioners are much larger and are usually installed on the warehouse floor.

Warehouse personnel typically roll a pallet onto the dimensioner using a pallet jack or place the shipment on the platform using a forklift. Once the pallet is in place, the dimensioner gathers weight, dimension, and volume data.

Before we go into the benefits of a parcel and pallet dimensioner, we invite you to read the factors to consider before adopting a parcel dimensioner or pallet dimensioner.

7 Benefits of a Parcel & Pallet Dimensioner

Parcel and pallet dimensioners are excellent additions to any warehouse. By implementing these devices into your workflow, your organization can:

1. Measure Dimensions and Weight Quickly

Pallet and parcel dimensioners use sensors to measure freight dimensions instantly. The devices use the height, width, and depth data to calculate the freight’s volume. They also gather weight data so that shippers can ensure their carriers are not overloaded.

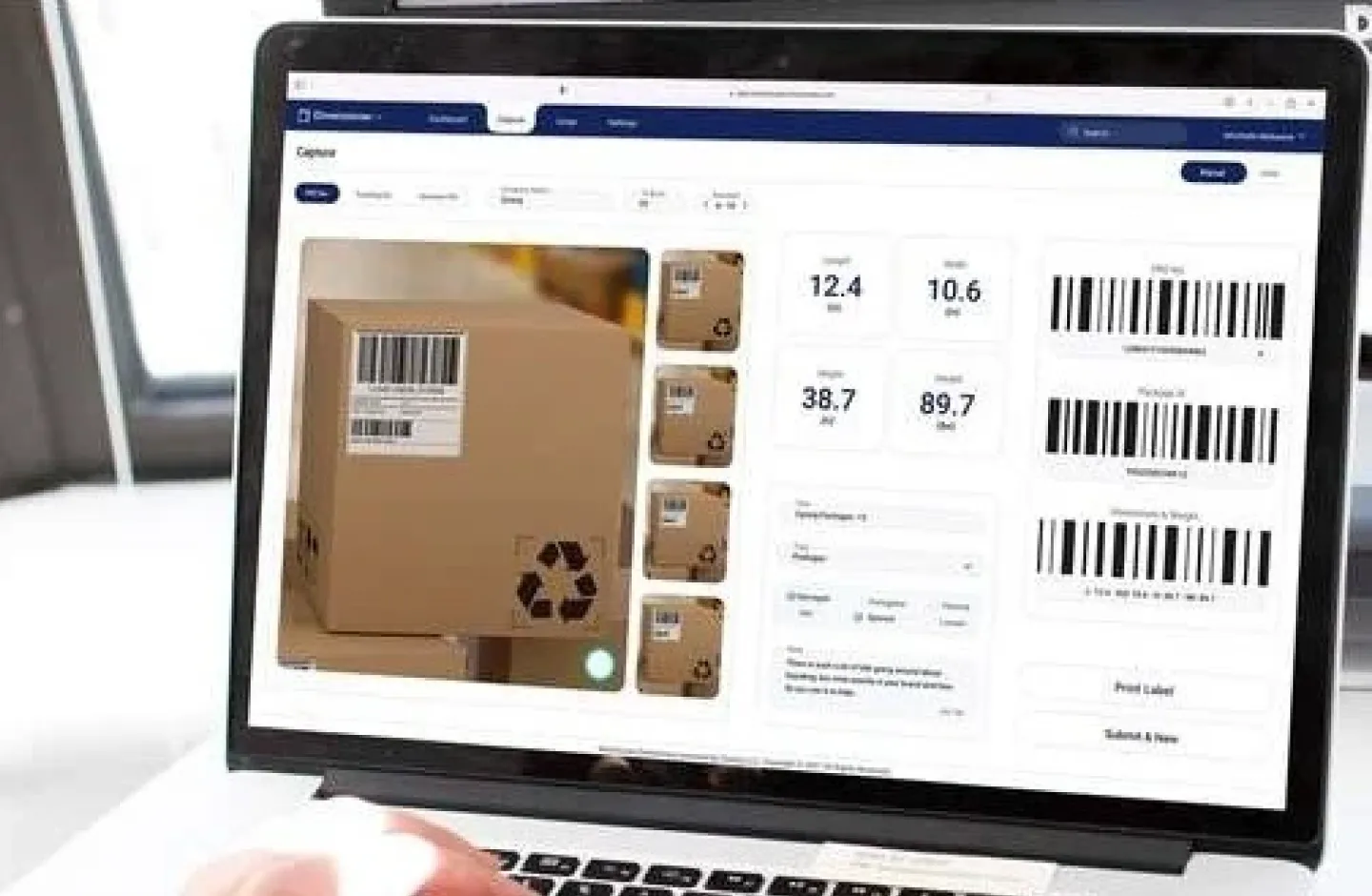

2. Instantly Capture Images of Cargo

Some dimensioners can capture images in addition to weight and dimensional data. Capturing images helps document the state of cargo when it is received or shipped out of your facility, proving it was in good condition. You also have proof if the cargo arrives damaged, which will help you protect your reputation and remedy the issue with downstream suppliers.

Incorporating image capture technology into dimensioners further reduces the workload of warehouse personnel. Instead of having to take and upload photos manually, your personnel can focus on more dynamic tasks while the dimensioner accelerates the freight-receiving process.

3. Obtain Accurate and NTEP-Certified Dimensions

Like scales, dimensioners can be certified by the National Type Evaluation Program (NTEP). Using NTEP-certified dimensioners ensures that all dimension and weight measurements are accurate and reliable.

In turn, this allows you to demonstrate your commitment to transparency and build trust with your clients. Charging clients based on NTEP-certified dimensions ensures billing accuracy and consistency across all shipments.

4. Automate Data Entry to Your WMS

If your facility still weighs or measures freight using traditional methods, your personnel must manually enter this data into your WMS. Manual data entry processes are not only inefficient, but they also increase the likelihood of an error.

Dimensioners can automatically enter data into your WMS after each package is scanned. This feature increases data accuracy and efficiency, enabling your facility to be more productive.

5. Reduce Dimension Processing Cost

Manually measuring the dimensions of parcels and pallets is expensive, inefficient, and tedious. With dimensioners, you can minimize dimension-processing costs by letting your staff perform the dimensioning process faster while eliminating errors.

6. Better Utilize Labor Resources

If you want to maximize the productivity of your facility, you need to optimize your labor resource utilization strategy. This means redirecting your staff away from unproductive tasks and assigning them more dynamic work.

Dimensioners reduce the amount of time it takes employees to gather dimensional data. You can also measure, weigh, photograph, and catalog shipments using less personnel. Those team members can now focus on more important or productive work.

7. Improve Employee Retention and Recruitment

Dimensioners will reduce the amount of mundane and repetitive work that employees have to perform. Ultimately, this can lead to better morale and improved retention.

Additionally, dimensioners may also support your recruiting efforts, especially with younger workers. With a median employee age of 38, the warehouse industry needs to find a way to connect with a younger generation. Adopting cutting-edge technology like dimensioners and robotic fulfillment tools can help with this effort.

Summary

Dimensioners are practical solutions for improving different aspects of your warehouse. Integrating pallet and parcel dimensioners into your warehouse helps elevate your productivity, increase labor resource utilization efficiency, and streamline your operations. It can also help your recruitment efforts penetrate the younger generation.

If you want to learn more about dimensioners, you can schedule a meeting with us on this page.

For more information about dimensioners or the latest warehouse technology trends, follow us on LinkedIn, YouTube, X, or Facebook. If you have other inquiries or suggestions, please contact us here. We’ll be happy to hear from you.