Efficiency is crucial for any fulfillment center aiming for success in today’s competitive market. To achieve heightened efficiency and cost-effectiveness, strategic decisions must be made and best practices adopted. These not only promise higher profitability but also ensure customer satisfaction. However, what are fulfillment centers using to increase efficiency?

In this article, we will explore the core practices and innovations that are shaping the future of fulfillment center operations. From cutting-edge inventory management systems to optimizing warehouse layouts for maximum efficiency and embracing automation technologies, we will dive into the key strategies of streamlining processes, minimizing errors, and saving valuable time and resources. But first, let’s establish a foundational understanding of what a distribution center entails and the pivotal role efficiency and cost savings play in its management.

What is a Distribution Center?

A distribution center (DC), sometimes called a distribution warehouse, is a specialized facility within the supply chain that primarily focuses on the receipt, storage, and distribution of goods to various destinations, such as retail stores, wholesalers, or direct customers. Distribution centers play a critical role in the logistics and supply chain management of companies by efficiently managing the movement of products from manufacturers or suppliers to their final destinations.

Importance of Efficiency and Cost Savings in Distribution Center Management

Efficiency and cost savings are crucial factors in the success of any distribution center. Businesses can streamline operations, reduce waste, and improve productivity by maximizing efficiency. This, in turn, leads to cost savings as resources are utilized more effectively and efficiently. Moreover, a well-managed distribution center can enhance customer satisfaction by ensuring timely and accurate order fulfillment.

To achieve these outcomes, it is essential to implement best practices that focus on optimizing various aspects of distribution center management. These practices not only enhance operational efficiency but also contribute to the bottom line. By investing time and effort in implementing these strategies, businesses can unlock the full potential of their distribution center and gain a competitive edge.

Key Challenges in Managing a Distribution Center

Managing a distribution center comes with its fair share of challenges. Identifying these challenges and addressing them proactively is crucial to ensure smooth operations and optimal performance. Some of the key challenges faced in distribution center management include:

1. Inventory Management

Maintaining accurate inventory records, managing stock levels, and preventing stockouts or overstock situations can be challenging. Without proper inventory management systems and processes, businesses may face increased costs, poor customer service, and inefficient order fulfillment.

2. Warehouse Layout and Design

A distribution center’s physical layout and design play a critical role in its operational efficiency. Inefficient warehouse layout can lead to wasted space, increased travel time, and errors in order picking. Optimizing the layout and design of the warehouse can significantly improve productivity and reduce costs.

3. Order Fulfillment Processes

Efficient and accurate order fulfillment is crucial for customer satisfaction. However, manual processes, lack of visibility, and ineffective workflows can lead to errors, delays, and increased costs. Streamlining order fulfillment processes through automation and technology can greatly enhance efficiency and reduce errors.

4. Tracking and Monitoring of Goods

Visibility and real-time tracking of goods are essential for effective distribution center management. Without proper tracking and monitoring systems, businesses may struggle with inventory accuracy, delayed shipments, and inefficient use of resources. Implementing technology solutions such as RFID and barcode scanning can improve tracking accuracy and enhance overall efficiency.

6 Best Practices to Optimize Distribution Center Operations

Optimizing distribution center (DC) operations is crucial for improving efficiency, reducing costs, and meeting customer demands. Here are some best practices to help you optimize your distribution center operations:

1. Optimize Warehouse Layout And Design

Optimizing the layout and design of a distribution center is crucial for improving efficiency and reducing costs. Here are some strategies to consider:

- Analyze Space Utilization: Conduct a thorough analysis of space utilization in the warehouse. Identify areas of wasted space and reorganize them to maximize storage capacity. This can be achieved by using vertical space, implementing proper racking systems, and optimizing aisle width.

- Implement Efficient Product Placement: Strategically place frequently picked items close to the shipping area to minimize travel time. Use data analysis to identify fast-moving products and allocate appropriate storage space accordingly. This will reduce picking time and improve overall efficiency.

- Create Efficient Picking Paths: Design picking paths that minimize travel time and eliminate unnecessary steps. Group products based on their frequency of picking to create efficient picking routes. This will reduce labor costs and improve order fulfillment speed.

- Create Efficient Picking Paths: Design picking paths that minimize travel time and eliminate unnecessary steps. Group products based on their frequency of picking to create efficient picking routes. This will reduce labor costs and improve order fulfillment speed.

2. Implementing Inventory Management Systems for Better Efficiency

Implementing inventory management systems can help businesses achieve better efficiency and cost savings. Here’s how:

- Centralize Inventory Data: Use an inventory management system to centralize and organize inventory data. This allows for real-time visibility and accurate tracking of stock levels, preventing stockouts or overstock situations.

- Automate Inventory Replenishment: Set up automated replenishment processes based on predefined thresholds. This ensures that inventory levels are maintained without manual intervention, reducing the risk of stockouts and overstock situations.

- Utilize Demand Forecasting: Implement demand forecasting techniques to predict future demand and adjust inventory levels accordingly. This helps businesses optimize inventory levels, reduce carrying costs, and improve order fulfillment.

- Integrate with Suppliers and Customers: Integrate the inventory management system with suppliers and customers to facilitate seamless communication and collaboration. This allows for better visibility, improved demand planning, and reduced lead times.

3. Streamlining Order Fulfillment Processes

Efficient order fulfillment processes are crucial for customer satisfaction and cost savings. Streamlining these processes can significantly improve overall efficiency and reduce errors. Here are some best practices to consider:

- Standardize Order Processing: Establish standardized order processing procedures to ensure consistency and accuracy. Clearly define the steps involved, from order receipt to shipment, and train employees accordingly.

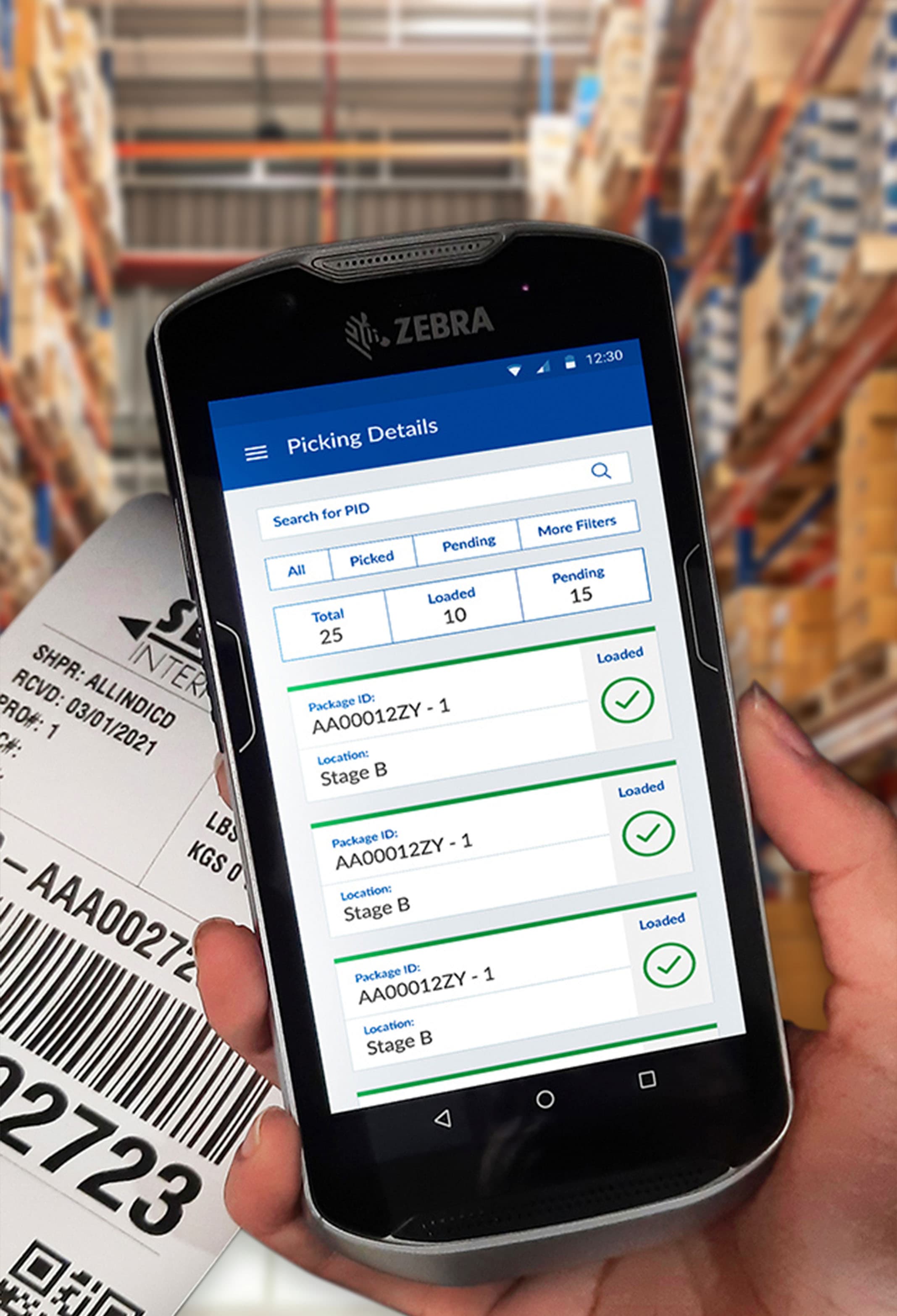

- Implement Barcode Scanning: Use barcode scanning technology to track and verify orders, minimize errors, and improve order accuracy. This technology enables real-time data capture and eliminates manual data entry.

- Optimize Picking and Packing: Implement efficient picking and packing techniques to reduce errors and improve speed. Consider batch picking, zone picking, or wave picking methodologies to optimize labor utilization and enhance productivity.

4. Using Technology to Improve Tracking and Monitoring Of Goods

Technology plays a vital role in optimizing distribution center operations. By leveraging technology solutions, businesses can improve tracking and monitoring of goods, improving efficiency and cost savings. Here’s how:

- Implement RFID Technology: RFID (Radio Frequency Identification) technology enables real-time tracking and monitoring of goods throughout the distribution center. This improves inventory accuracy, visibility, and overall efficiency.

- Utilize Barcode Scanning: As an alternative to RFID, barcode scanning technology allows for accurate and efficient tracking of goods. By scanning barcodes at various stages of the distribution process, businesses can improve visibility, reduce errors, and enhance overall efficiency.

- Utilize GPS Tracking: GPS (Global Positioning System) tracking can be used to track shipments in real time. This provides businesses with accurate information on the location and status of goods, enabling better planning and timely delivery.

- Implement Warehouse Management Systems (WMS): WMS software gives businesses centralized control and visibility over distribution center operations. It enables efficient order management, inventory tracking, and resource allocation, improving efficiency and cost savings.

![]()

5. Implementing Lean Principles for Waste Reduction and Increased Productivity

Lean principles are a proven methodology for waste reduction and increased productivity in distribution center management. By implementing these principles, businesses can eliminate non-value-added activities, reduce costs, and improve overall efficiency. Here’s how to apply lean principles:

- Identify and Eliminate Waste: Conduct a thorough analysis of distribution center processes to identify areas of waste. This can include excessive movement, overproduction, waiting time, and unnecessary inventory. By eliminating waste, businesses can achieve cost savings and improve efficiency.

- Implement 5S Methodology: The 5S methodology (Sort, Straighten, Shine, Standardize, Sustain) focuses on creating a clean and organized work environment. By implementing 5S principles, businesses can improve efficiency, reduce errors, and enhance overall productivity.

- Embrace Continuous Improvement: Establish a culture of continuous improvement within the distribution center. Encourage employees to identify areas for improvement and implement solutions. This ensures that the distribution center constantly evolves and strives for better efficiency.

- Implement Visual Management: Use visual techniques such as visual cues, signage, labels, and color coding to enhance communication and improve productivity. Visual management enables quick identification of issues, reduces errors, and enhances overall efficiency.

6. Training and Development Programs for Distribution Center Staff

Investing in the training and developing distribution center staff is essential for achieving efficiency and cost savings. Well-trained employees are more productive, make fewer errors, and contribute to a positive work environment. Here are some best practices for training and development:

- Provide Comprehensive Onboarding: Ensure new employees receive comprehensive onboarding training covering the distribution center’s processes, systems, and safety procedures. This sets the foundation for their success and ensures they understand their roles and responsibilities.

- Offer Ongoing Training: Provide ongoing training opportunities to enhance employees’ skills and knowledge. This can include training on new technologies, process improvements, safety protocols, and customer service. Ongoing training keeps employees engaged and updated on best practices.

- Encourage Cross-Training: Cross-train employees on various tasks and roles within the distribution center. This enables flexibility in resource allocation, improves cross-departmental collaboration, and enhances overall efficiency.

- Promote a Culture of Learning: Foster a culture of learning and continuous improvement within the distribution center. Encourage employees to seek learning opportunities, share knowledge, and contribute ideas for process optimization. This creates an engaged and empowered workforce.

Conclusion: Unlocking Efficiency and Cost Savings in Distribution Center Management

Managing a distribution center efficiently is critical for businesses looking to stay competitive and achieve cost savings. Efficiency and cost savings not only lead to higher profitability but also contribute to enhanced customer satisfaction. By continuously striving for improvement and implementing the best practices above, businesses can revolutionize their distribution center operations, paving the way for increased efficiency and cost savings.

For more content about warehouse efficiency or the latest technology trends, follow us on LinkedIn, YouTube, X, or Facebook. If you have other inquiries or suggestions, please contact us here. We’ll be happy to hear from you.